- Apr 18, 19

- FQA

- 5092 views

How to conduct a product quality inspection in a China factory

If you let a Chinese supplier ship the goods out without inspecting them, and if you discover quality problems after delivery in your country, is there anything you can do? For most importers, the reply is no.

-

Chances are, by that time you have already paid the supplier in full. And there is little hope of getting any of your cash back. You might be offered a discount on a future order, but do you still want to work with such a supplier?

-

What can you do with the defective products? If you sell them in a distribution channel that does not make exceptions to its quality standard, you might as well have to take a trip to the local dump.

-

Reproducing the same goods in another factory might take a long time. In the meantime, what do you tell your customers (especially if they are the ones who found out about these quality issues)?

In a nutshell, the final quality inspection is the last defense of the customer!

If the size of your orders does not justify the cost of at least one inspection before shipment, you need to mitigate your risks in any way you can - for example, by always working with the same reliable manufacturer, and by keeping some stock in your warehouse at all time (in case a shipment needs to be scrapped).

2. At what stage should you check production quality?

It depends on the major risks you identify:

-

If the main risk is that your supplier purchases substandard materials (or components), it is wise to check them as soon as they are delivered (and before production starts, IQC).

-

If you know that a particular process step is the most likely cause of failure, you should check the way that step is conducted.

-

If you are not sure about what type of problem might appear in production, checking the first batch of finished products is a good way to catch problems before they become widespread - and to ensure corrective actions are taken.

-

If you feel relatively confident about the factory's quality standard, but you still want an inspection of the quantity, product quality and functionality, and packing, a final random inspection (a few days before shipment) is the right choice. I do not advise to wait until the end of production if you are dealing with an untested or unstable supplier.

The two most common types of inspections are:

1. The final random inspection, because it is the only time when samples can be picked at random and when most of the bulk is packed.

2. The final inspection of the first finished products, to catch issues as early as possible.

But when do the first finished products appear?

It really depends on the organization of production:

-

In a traditional batch and queue production system, your products are kept in an unfinished process during most of the cycle, often for several weeks. They go all together through one operation, then they wait, then they go through another one, and so on. Depending on the type of processes your order needs to go through, the first finished pieces might appear after three weeks, and the whole order might be packed a few days later!

-

In a system where products flow more easily from one process step to the next, some products are completed much earlier. An inspection of the first

If you let a Chinese supplier ship the goods out without inspecting them, and if you discover quality problems after delivery in your country, is there anything you can do? For most importers, the reply is no.

-

Chances are, by that time you have already paid the supplier in full. And there is little hope of getting anyof your cash back. You might be offered a discount on a future order, but do you still want to work with such a supplier?

-

What can you do with the defective products? If you sell them in a distribution channel that does not make exceptions to its quality standard, you might as well have to take a trip to the local dump.

-

Reproducing the same goods in another factory might take a long time. In the meantime, what do you tell your customers (especially if they are the ones who found out about these quality issues)?

In a nutshell, the quality inspector is the last defense of the customer!

If the size of your orders does not justify the cost of at least one inspection before shipment, you need to

mitigate your risks in any way you can - for example, by always working with the same reliable manufacturer, and by keeping some stock in your warehouse at

all time (in case a shipment needs to be scrapped).

2. At what

stage should you check production quality?

It depends on the major risks you identify:

-

If the main risk is that your supplier purchases substandard materials (or components), it is wise to check them as soon as they are delivered (and before production starts).

-

If you know that a particular process step is the most likely cause of failure, you should check the way that step is conducted.

-

If you are not sure about what type of problem might appear in production, checking the first batch of finished products is a good way to catch problems before they become widespread - and to ensure corrective actions are taken.

-

If you feel relatively confident about the factory's quality standard, but you still want an inspection of the quantity, product quality and functionality, and packing, a final random inspection (a few days before shipment) is the right choice. I do not advise to wait until the end of production if you are dealing with an untested or unstable supplier.

The two most common types of inspections are:

1. The final random inspection,because it is the only time when samples can be picked at random and when most of the bulk is packed.

2. The inspection of the first finished products (Initial Production Check), to catch issues as early as possible.

But when do the first finished products appear?

It really depends on the organization of production:

-

In a traditional batch and queue production system, your products are kept in an unfinished process during most of the cycle, often for several weeks. They go all together through one operation, then they wait, then they go through another one, and so on. Depending on the type of processes your order needs to go through, the first finished pieces might appear after three weeks, and the whole order might be packed a few days later!

-

In a system where products flow more easily from one process step to the next, some products are completed much earlier. An inspection of the first finished products is well suited for this situation, while the previous case calls for a final random inspection only.

3. Checking production status

3.1 If production is under way

You might want to ask these questions:

-

How many lines are working on these products?

-

How many workers per line, and total number of workers on these products?

-

When were the last materials / components delivered?

-

Has bulk production started? When?

-

When did/will bulk production start

to run at full speed?

-

How many pieces are processed every

day?

-

When does the factory estimate that

50 percent of the quantity will be completed?

-

When does the factory estimate that

100 percent of the quantity will be fully packed?

-

When does the factory estimate that

the order will be shipped out?

-

Will the full quantity be shipped

out?

3.2 If production is in an advanced stage

If you come for a final quality inspection, you

need to put pressure on the manufacturer to present all the products (or at

least 80 percent of them) fully packed. Above a certain order quantity, this is

the only way for you to count the pieces. And this is important because you

want to pick samples from the entire production run - you do not want 30

percent of the goods to be hidden in a back room!

Important note: if some products are

packed and others are waiting to be packed, make sure to pick both unpacked and

packed samples - ideally in the same proportions as the total batch.

4. Checking

product and packing specifications

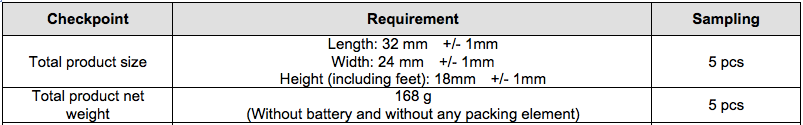

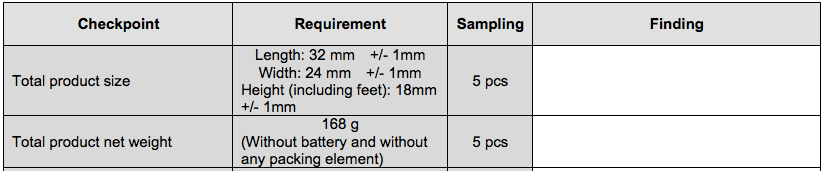

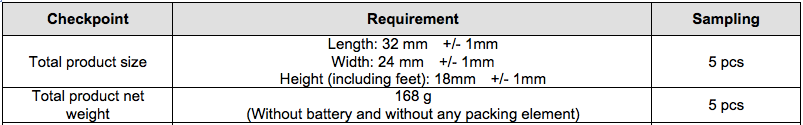

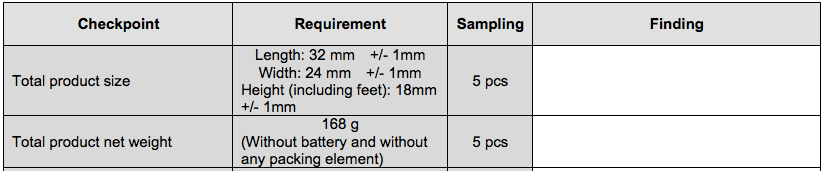

4.1 Preparing the checklist

Now is the time to make use of the product

specification sheet that, hopefully, you have prepared before production started.

Before in-line inspection,

you simply need to paste the checkpoints and requirements (from the

specification sheet) into the columns on the left of the quality inspection template.

And, during the onsite inspection, you enter findings on the right (in the white

column).

This information coming from the product

specification sheet...

...is pasted this way in the product

inspection report:

4.2 Notes about the template

-

Sampling, by default, is 5 pieces in the template you can download at the top of this article. But you should feel free to adjust this number. If all the products get off the same mold, you might want to measure only 1 piece. If there is more variation due to a hand-making process, or if a checkpoint is particularly important, do not hesitate to increase the sample size.

-

This template is applicable for checking one type of product. If there are several items, you will need to make adjustments in the format.

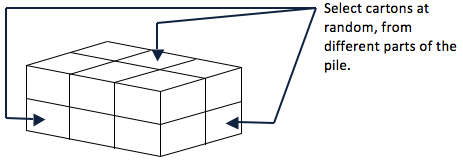

4.3 The procedure to follow

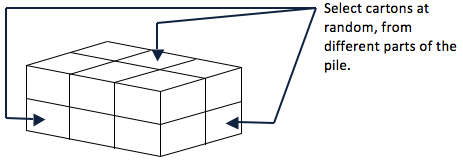

-

The number of cartons to

pick up should be at

least the square root of the total number of cartons in the order.

Example: at least 8 cartons if there is a total of 50 cartons.

-

The inspector must select export

cartons from different parts of the pile -- from the top, from the bottom,

from the sides, and from the center.

-

Once the cartons are opened, start by

taking a few pieces (it depends on the sampling you chose for the product

and packing QC inspection). Make sure you take these pieces from the top,

middle, and bottom of the cartons.

-

Keep the cartons near you, if

possible. You will need to draw more pieces for the next part of the inhouse inspection.

5. Checking

visual defects

5.1 Checking more samples

After checking a few cartons and a few

pieces in detail, you need to check more products visually. You will look for

aesthetic defects (for example, stains, scratches, poor alignment), but you

should also run quick tests (for example, plugging in an electrical product and

switching it on/off, or stretching the stitching of a garment).

You should only select a few "quick

tests" to check on all samples. Actually, you will need to make a trade

off. Conducting many tests (or a few time-consuming tests) on the whole sample

size might take you a lot of time. But if you do not run any test on the whole

sample size, you might miss some quality issues.

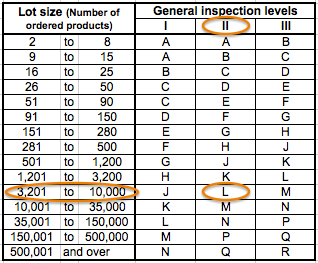

5.2 Following industry-standard statistical

rules

I strongly advise to draw a representative

sample by following industry-standard statistical rules (MIL-STD 105E or commercial equivalents

ANSI/ASQC Z1.4, ISO2859).

These rules will give you two pieces of

information:

-

How many samples you should pick up

from cartons and check visually.

-

What the limits in the number of

defects (beyond which the inspection is failed) are.

5.3 How many samples to check this way?

For simplicity, let us say you follow the

same settings as 90 percent of importers of consumer goods:

There are two statistical charts that you

need to be familiar with:

-

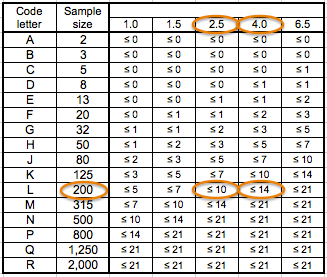

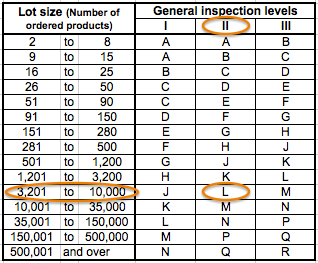

First table: Sample size code letters

Let us assume that the order quantity is

comprised between 3,201 pieces and 10,000 pieces. The code letter is

"L".

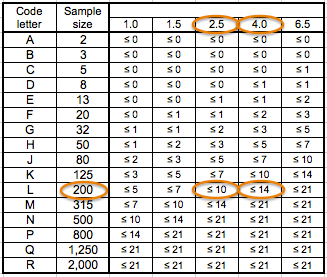

2. Second table: Single sampling

plans for level II inspection (normal severity)

Your code letter is "L", so you

will have to draw 200 pieces randomly from the total lot size.

And here are the limits -- the products

are accepted if NOT A SINGLE critical defect AND NO MORE than 10 major defects

AND NO MORE than 14 minor defects are found.

6. Checking

the loading of a container

Like in part 4, you will need to define

your requirements before conducting the Shipment Inspection. Here is some information

you should try to specify:

6.1 The products to ship

-

Conformity to the buyer's requirements (did the factory swap the products before shipment?)

-

Total quantity

6.2 The packing

-

Number of cartons to be loaded

-

Number of pieces per carton

-

Numbering of cartons

-

Pallets size, weight, and material,

if applicable

-

Number of cartons per pallet, if

applicable

6.3 Condition of the container(s)

-

Containers are in good condition,

inside and outside. They should not have any holes, strong smell or

humidity;

-

A seal is affixed to close each

container, with a unique number.

6.4 The loading process

-

No carton should fall on the ground

or be damaged when the factory loads the cartons;

-

If a loading plan was given to the

manufacturer, is it respected?

If not, are the heaviest and strongest

cartons loaded at the bottom?