As a sourcing company having operated for many years, we have heard all sorts of quality objectives in colloquial terms. They sound very straight forward and reflect our clients fundamental desires to offer the best possible quality to his/her customers.

A very crucial part of the work in sourcing and purchasing is to defining in professional words and numbers what the supplier and the customer should agree upon, assure compliance and deal with breaches.

Before we elaborate on the three components of the quality management for international procurement, it is necessary to stress selecting the right supplier and gaining the access to the production are the prerequisite for all the measures I am going to write about the following texts.

Defining quality

A good quality definition starts with a well worded and sampled product specification.

Starting with the supplier’s own literature is a practical way of specifying the product because it is something that the supplier sells and the customer accepts. Further work needs to be done to complete the specification. Keep the below guidelines in mind

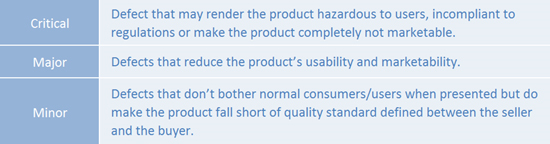

It is a widely well accepted reality that in a certain batch of produced product, there will be defects of a certain level. Oh, I do not need any defect, give me 100% good ones. Is a common request when a client is asked of quality. We will need to agree with the supplier a certain level of AQL, or Acceptable Quality Limits. The AQL is the quality level that is the worst tolerable percentage of defects. Usual AQL are 0.65, 1.0, 1.5, 2.5, 4.0, 6.5. For example, if your AQL is 1 but the statistics from a sampling inspection process shows that it is very likely that the population (the whole lot) has more than 1% defects, then the lot should be rejected. In most cases, three categories of defects are defined because different category may have different significance of impact on the acceptability of the product. Example categories are:

Different companies may have different classification on the definition of categories. Experienced buyers or sellers have a very good idea of possible defects of the products. What in the quality defining process is to list all possible quality defects and assign them to the categories as listed above. You can consider applying 0.65% to the critical defect, 2.5% to the major defect and 4.0% to the minor defects.

Assuring compliance

Building perception of your seriousness in the whole communication process will help you bring the supplier’s attentions to quality. Make them aware that if quality defects are found to be incompliant, they may get their lots rejected.

You need to understand what quality procedures the suppliers have in house. If you deal with multiple factories you may find that they may have different internal procedures for their on line quality check. We know a glass packaging factory makes a mould stability report of all the cavities on a running product every 20 minutes and they log all the dimensions of the neck, the body etc, whereas another factory only check every 1 hour and they only log 'pass', 'fail’. Having such information makes it possible to request the factory to provide with critical information in the process, so you can be reassured that they are not skipping their necessary quality steps because of rush, laziness, etc.

Sending an inspector to check in the middle of the production would help a lot. The factory may neglect some key quality characteristics that are very important to you but not to them. Having an inspector that really knows by heart your requirements is very important, as he can help spot such problems, especially in the case where you have multiple suppliers.

Dealing with noncompliance

The last thing we want to see in an order is quality noncompliance at the final inspection. Do everything you can to avoid it, select the supplier with the best quality attitude and procedure in place, make clear your requirements of quality and make due efforts in the process of product.

If unfortunate enough the quality is incompliant and you have every evidence that it is not your fault, discuss a solution with the supplier. Possible outcomes are cancellation of order, rework, reduction of prices, extra parts. Try your best effort to be fair while keeping yourself from being harmed by the quality issues, by negotiating proper remedies by the supplier. Take note of this breach, and reduce the ranking of this particular supplier in your list unless he proves to you that adequate correctional measures has been taken to avoid the same problem in the future.